Welcome again friends,

In the last blog I told you all about turbocharge and supercharge engines and so today I am going so tell u about component of four stroke engine.

To know what four stroke engine you can view my other blogs.

So lets start with the topic

All four-stroke internal combustion engines employ valves to control the admittance of fuel and air into the combustion chamber. Two-stroke

engines use ports in the cylinder bore, covered and uncovered by the

piston, though there have been variations such as exhaust valves.

Internal combustion engines have to effectively manage the exhaust of

the cooled combustion gas from the engine. The exhaust system

frequently contains devices to control both chemical and noise

pollution. In addition, for cyclic combustion engines the exhaust system

is frequently tuned to improve emptying of the combustion chamber. The

majority of exhausts also have systems to prevent heat from reaching

places which would encounter damage from it such as heat-sensitive

components, often referred to as Exhaust Heat Management.

Combustion generates a great deal of heat, and some of this transfers

to the walls of the engine. Failure will occur if the body of the

engine is allowed to reach too high a temperature; either the engine

will physically fail, or any lubricants used will degrade to the point

that they no longer protect the engine. The lubricants must be clean as

dirty lubricants may lead to over formation of sludge in the engines.

A piston is a component of reciprocating engines. It is located in a cylinder and is made gas-tight by piston rings. Its purpose is to transfer force from expanding gas in the cylinder to the crankshaft via a piston rod and/or connecting rod. In two-stroke engines the piston also acts as a valve by covering and uncovering ports in the cylinder wall.

For jet engine forms of internal combustion engines, a propelling nozzle is present. This takes the high temperature, high pressure exhaust and expands and cools it. The exhaust leaves the nozzle going at much higher speed and provides thrust, as well as constricting the flow from the engine and raising the pressure in the rest of the engine, giving greater thrust for the exhaust mass that exits.

Most reciprocating internal combustion engines end up turning a

shaft. This means that the linear motion of a piston must be converted

into rotation. This is typically achieved by a crankshaft.

The flywheel is a disk or wheel attached to the crank, forming an inertial mass

that stores rotational energy. In engines with only a single cylinder

the flywheel is essential to carry energy over from the power stroke

into a subsequent compression stroke. Flywheels are present in most

reciprocating engines to smooth out the power delivery over each

rotation of the crank and in most automotive engines also mount a gear

ring for a starter. The rotational inertia of the flywheel also allows a

much slower minimum unloaded speed and also improves the smoothness at

idle.

These systems often work in combination with engine cooling and

exhaust systems. Heat shielding is necessary to prevent engine heat from

damaging heat-sensitive components. The majority of older cars use

simple steel heat shielding to reduce thermal radiation and convection. It is now most common for modern cars are to use aluminium heat shielding which has a lower density, can be easily formed and does not corrode in the same way as steel.

Higher performance vehicles are beginning to use ceramic heat shielding

as this can withstand far higher temperatures as well as further

reductions in heat transfer.

.

THANKS FOR WATCHING

In the last blog I told you all about turbocharge and supercharge engines and so today I am going so tell u about component of four stroke engine.

To know what four stroke engine you can view my other blogs.

So lets start with the topic

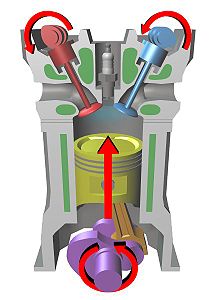

For a four-stroke engine, key parts of the engine include the crankshaft (purple), connecting rod (orange), one or more camshafts (red and blue), and valves. For a two-stroke engine, there may simply be an exhaust outlet and fuel inlet instead of a valve system. In both types of engines there are one or more cylinders (grey and green), and for each cylinder there is a spark plug (darker-grey, gasoline engines only), a piston (yellow), and a crank pin (purple). A single sweep of the cylinder by the piston in an upward or downward motion is known as a stroke. The downward stroke that occurs directly after the air-fuel mix passes from the carburetor or fuel injector to the cylinder (where it is ignited) is also known as a power stroke.

Valves

Piston engine valves

In piston engines, the valves are grouped into 'inlet valves' which admit the entrance of fuel and air and 'outlet valves' which allow the exhaust gases to escape. Each valve opens once per cycle and the ones that are subject to extreme accelerations are held closed by springs that are typically opened by rods running on a camshaft rotating with the engines' crankshaft.Control valves

Continuous combustion engines—as well as piston engines—usually have valves that open and close to admit the fuel and/or air at the start up and shutdown. Some valves feather to adjust the flow to control power or engine speed as well.Exhaust systems

Cooling systems

Piston

Propelling nozzle

For jet engine forms of internal combustion engines, a propelling nozzle is present. This takes the high temperature, high pressure exhaust and expands and cools it. The exhaust leaves the nozzle going at much higher speed and provides thrust, as well as constricting the flow from the engine and raising the pressure in the rest of the engine, giving greater thrust for the exhaust mass that exits.

Crankshaft

Flywheels

Starter systems

All internal combustion engines require some form of system to get them into operation. Most piston engines use a starter motor powered by the same battery as runs the rest of the electric systems. Large jet engines and gas turbines are started with a compressed air motor that is geared to one of the engine's driveshafts.Heat shielding systems

Lubrication systems

Internal combustion engines require lubrication in operation that moving parts slide smoothly over each other. Insufficient lubrication subjects the parts of the engine to metal-to-metal contact, friction, heat build-up, rapid wear often culminating in parts becoming friction welded together e.g. pistons in their cylinders. Big end bearings seizing up will sometimes lead to a connecting rod breaking and poking out through the crankcase..

Control systems

Most engines require one or more systems to start and shut down the engine and to control parameters such as the power, speed, torque, pollution, combustion temperature, and efficiency and to stabilise the engine from modes of operation that may induce self-damage such as pre-ignition. Such systems may be referred to as engine.THANKS FOR WATCHING

No comments:

Post a Comment